Streamline day-to-day warehouse operations and workflows to maximize resources utilization

Imprecise information of inventory level and redundant processes can lead to affect productivity, shipment schedule, stock availability and customer satisfactions for warehouses or distribution centers. Maximized space utilization, optimized route plan operations and timely accurate information is critical to success in today’s competitive market of warehouse management.

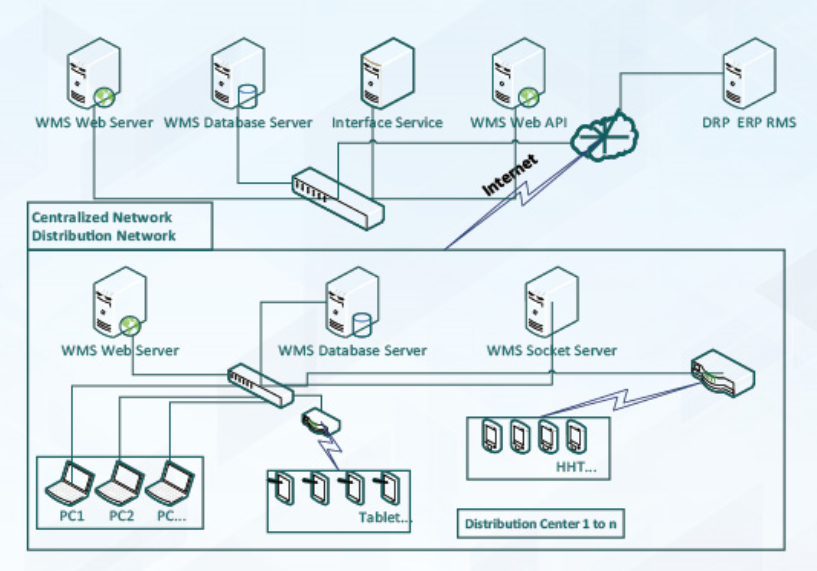

Therefore, a sophisticated Warehouse Management System (WMS) is vital, it can provide a solid foundation of industry best practices for receiving, put-away, inventory management, order processing, replenishment, picking / packing as well as loading and shipping. With the use of wireless infrastructure, voice directed picking, and Auto-ID technologies, it enables automated operation processes and real-time visibility of inventory resulting in timely accurate information for better business decision-making.

In addition, the enablement of EDI helps facilitate timely exchange of purchase orders, invoices, advance ship notices (ASNs) and other business transactions with ERP, accounting or other business systems connected seamlessly via electronic means. Various aspects on warehouse operations such as inventory tracking, order processing and goods return can be benefited owing to the improvement of information accuracy, operation efficiency and costs reduction.

Use RF handheld devices to reduce/eliminate tagging;

Bar code management, realize paperless, reduce manual input errors

Storage optimization strategies

Route optimization recommendations

Inventory warnings and procurement proposals

Labor Efficiently assessment

Realize maximum of equipment utilization

Real-time data transmission through wireless network

Real-time feedback on inventory information

Staff performance can be tracked

System data traceable, reducing/eliminating physical inventory

Shanghai Beijing Guangzhou

Shenzhen Xiamen Chengdu

Hong Kong Taiwan Korea Thailand

Singapore Malaysia Philippines